If your latest project calls for A490 bolts, here is everything you need to know about these special types of structural bolts. Learn what they are, how they work, and how to get the bolts you need soon as possible.

What Are A490 Bolts?

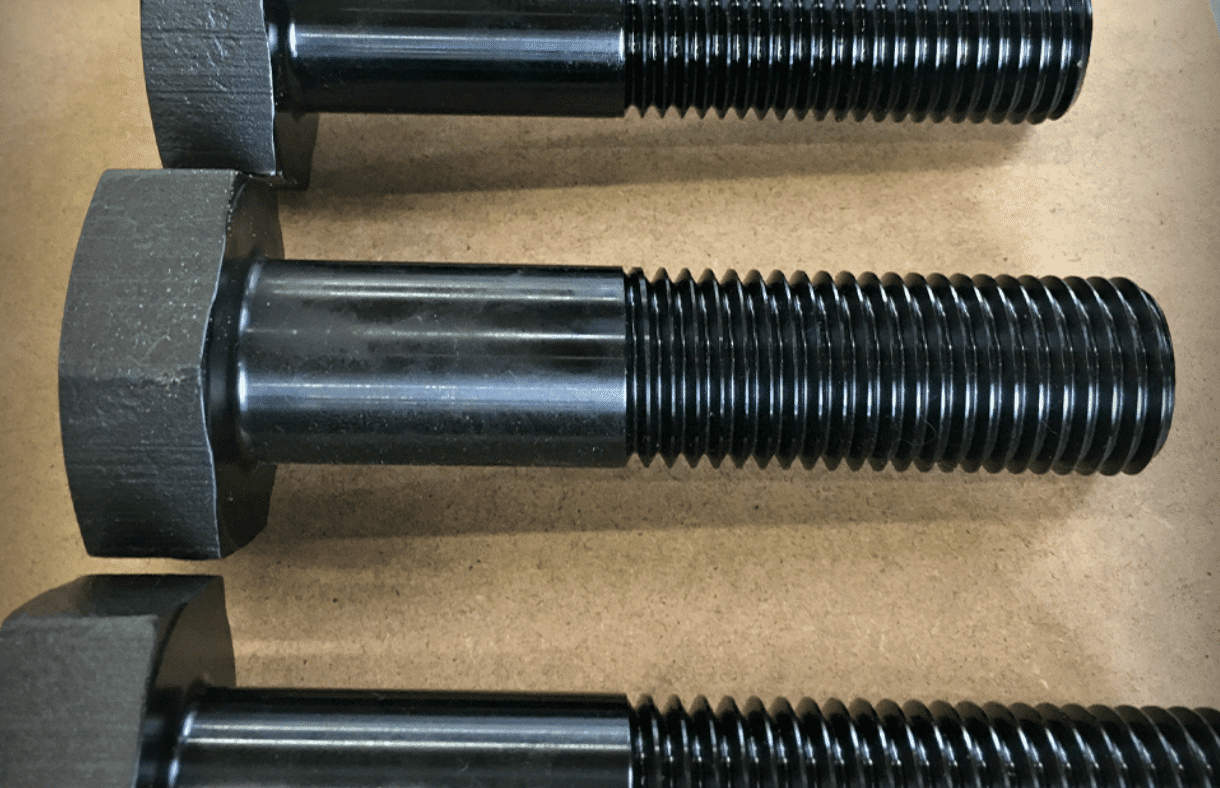

These types of bolts are fasteners that meet the ASTM A490 standard, hence their name. The key features of these structural bolts include the following:

- Minimum tensile strength of 150 KSI

- Alloy steel composition

- No hot dip coating

- Shorter thread lengths

- Heavy hexes

- Higher strength

They are used in a variety of high-stress applications. Some use cases for these bolts include the following industries:

- Military marine equipment

- Bridges

- Locks

- Dams

- Highway signage

- Wind tower construction

All of these projects call for high-strength fasteners and require large, durable bolts, which is why project leaders use the A490 type of bolt for these exact applications. These particular bolts must also be tested using magnetic particle inspection; otherwise, they cannot be classified as such.

A490 vs. A325 bolts

Though similar to A325 heavy hex structural bolts, there are a few key differences that set A490 bolts apart.

For one, A325 bolts, despite being very reliable in their own right, don’t compare to the tensile strength offered by A490 bolts due to the materials from which each bolt is made.

The forging process also influences the strength of each bolt, and the specific process for A490 bolts is slightly different from that of A325s. A325 bolts are made from carbon steel, whereas A490 bolts are made from alloy steel.

The coating process also differs between the two. ASTM prohibits A490 bolts from being coated through:

- Hot dip galvanizing

- Mechanical deposition

- Electroplating with zinc

These methods are forbidden because they can compromise the integrity of the bolts. However, A490 bolts can be coated with aluminum or zinc corrosion-resistant coating, a substance commercially known as Dacromet.

What Projects Are A490 Bolts Used For?

These tough bolts are used for structural applications and can withstand prolonged exposure to heavy loads.

They are available in many different lengths and diameters – up to 60 feet and 26 inches, respectively – and at the largest, they can weigh as much as 10,000 pounds. On the opposite end, some of these bolts can weigh in at amounts as small as half a pound and be available in lengths and diameters as short as half an inch.

Options for Acquiring A490 Bolts

When you need this type of bolt, it is vital to source them from a reputable manufacturer. ASTM standards exist for a reason, and if a particular manufacturer does not follow them, your bolts may underperform as a result.

When searching for a supplier, you can choose either an offshore or domestic option, such as Dyson Corp. Let’s examine the pros and cons of each.

1. Offshore Suppliers

Offshore suppliers often offer this type of bolt at a relatively low cost, which can be appealing when your budget is already overstretched. Be that as it may, these cost savings come at a price:

- Offshore options exhibit inconsistent quality.

- You may receive mixed batches of bolts from more than one manufacturer.

- Delivery timetables become an issue when working with offshore suppliers.

- Order delays lead to project delays.

Overall, the expenses associated with these delays can erase any cost savings you may initially gain by using an offshore supplier, meaning offshore suppliers can be more challenging than it’s worth if you need quality bolts when needed.

2. Domestic Suppliers

Domestic suppliers will provide you with the bolts you need made right here in America. The bolts must adhere to the strict ASTM standards, ensuring consistent product quality and performance.

Domestic suppliers can also get you your bolts fast, helping you avoid delays and keeping your project moving forward.

Cost is the only real “downside” to sourcing your bolts from a domestic provider. Still, any per-unit cost increases are more often than not offset by the product quality and delivery timetable benefits.

So if you need this type of bolt, sourcing them from a domestic supplier like Dyson is your best option.

Why Dyson for A490 Bolts?

If you want A490 bolts that are reliably made in America, Dyson Corp. can help. We can provide you with top-quality products, along with any other fasteners you may need for your industrial project. When you work with us, you’ll enjoy the following benefits:

- World-class customer service

- Unmatched product quality

- Short delivery timetables

If you’re ready to work with a premier U.S. supplier, contact Dyson Corp. today to obtain a quote on bolts for your next job.