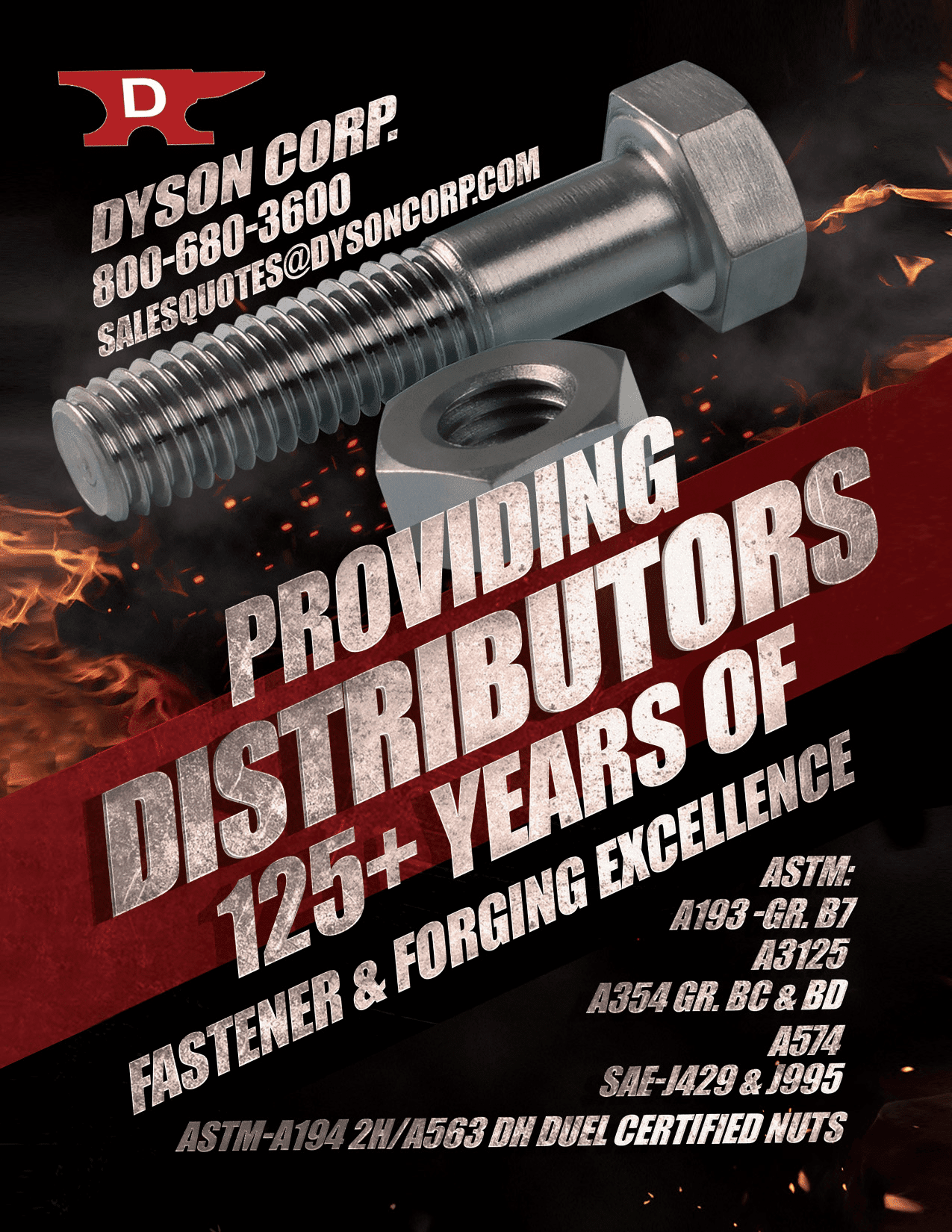

For over 125 years, Dyson Corp. has remained North America’s leading producer of high quality, 100% domestic, large diameter fasteners and forgings. Serving the critical markets of Renewable Energy, Marine and Military, Oil and Gas, Infrastructure, State Departments of Transportation, Mining, Hydropower, General Construction, and Bridge Construction/Restoration, their products are present in some of America’s most notable projects.

All products manufactured at the company’s Painesville, Ohio facility are strictly 100% melted and manufactured in the U.S.A., and are produced to various specifications including ASME, ASTM, SAE, MIL, ANSI and DIN… making Dyson America’s number one source for domestically produced parts for use on large scale projects.

“All Dyson products are of the highest quality standard and are fully traceable back to raw material production” claims Mike Robinson, Head of Dyson Sales for Construction Components.

Recently, Dyson made a significant investment in two high-speed bolt forging presses. This new capability allows them to rapidly produce blank bolts, cap screws and clevis pins 30% faster than prior manufacturing methods. Dyson can hot forge bolts up to 2.25” in diameter, and with their own on-site heat-treating facility, the company is able to stock bolts in multiple grades and specifications.

“Our new bolting capabilities allow us to respond to large or small orders effectively and provides our distribution partners with even faster turn-arounds,” says John Hocevar, Head of Dyson’s Forged Technology line.

Hocevar further declares “Dyson is distinct among other nut and bolt manufacturers in that it is the only manufacturer to duel certify ASTM-A194 grade 2H/ASMT-A563 grade DH heavy hex nuts.”

This benefits Dyson’s distribution customers by allowing them to better manage their inventory, ultimately cutting their number of stocked sku’s in half since they no longer have to stock 2H and DH nuts in their warehouses. “Our 2H/DH heavy hex nuts save our customers money, time and space,” states Hocevar.

Dyson’s duel certified nuts are available in diameters 1.25” up to 4” in plain finish, as well as galvanized. They can also forge up to 6.5” diameter heavy hex nuts and can accommodate customized requirements.

In addition to their duel certified 2H/DH nuts, Dyson Corp. is also unique in the industry due to their various patents. They are the patent holder of the original D-LOC and M-LOC free spinning lock and seal nuts which are widely used on applications that require vibration or liquid leakage minimization such as the mining industry. Most major mining companies use Dyson’s D-LOC nuts on their crusher and shaker equipment, and they’re also commonly used on other vibration prone applications such as railway systems.

“Dyson is the only manufacturer to produce D-LOC heavy hex nuts where complete thread engagement is achieved. This fully forged nut provides maximum strength and tension values for extreme working environments,” explains Patrick Linehan, Director of Engineering at Dyson Corp. Linehan further clarifies, “Dyson’s D-LOC nuts distribute the bearing load on irregular surfaces and locks the bolt and nut assembly together. It also creates a water-tight seal. Vibration cannot loosen the assembly due to the locking element of this product.”

To find out more about what Dyson can offer and how they fulfil your forging and fastener needs, contact: Chelsea Johnson at [email protected].

You can see the full online feature here.