The brave men and women of the U.S. military are the most important assets in our nation’s commitment to defense at home and abroad. Those individuals must have access to the tools they need to perform mission-critical duties.

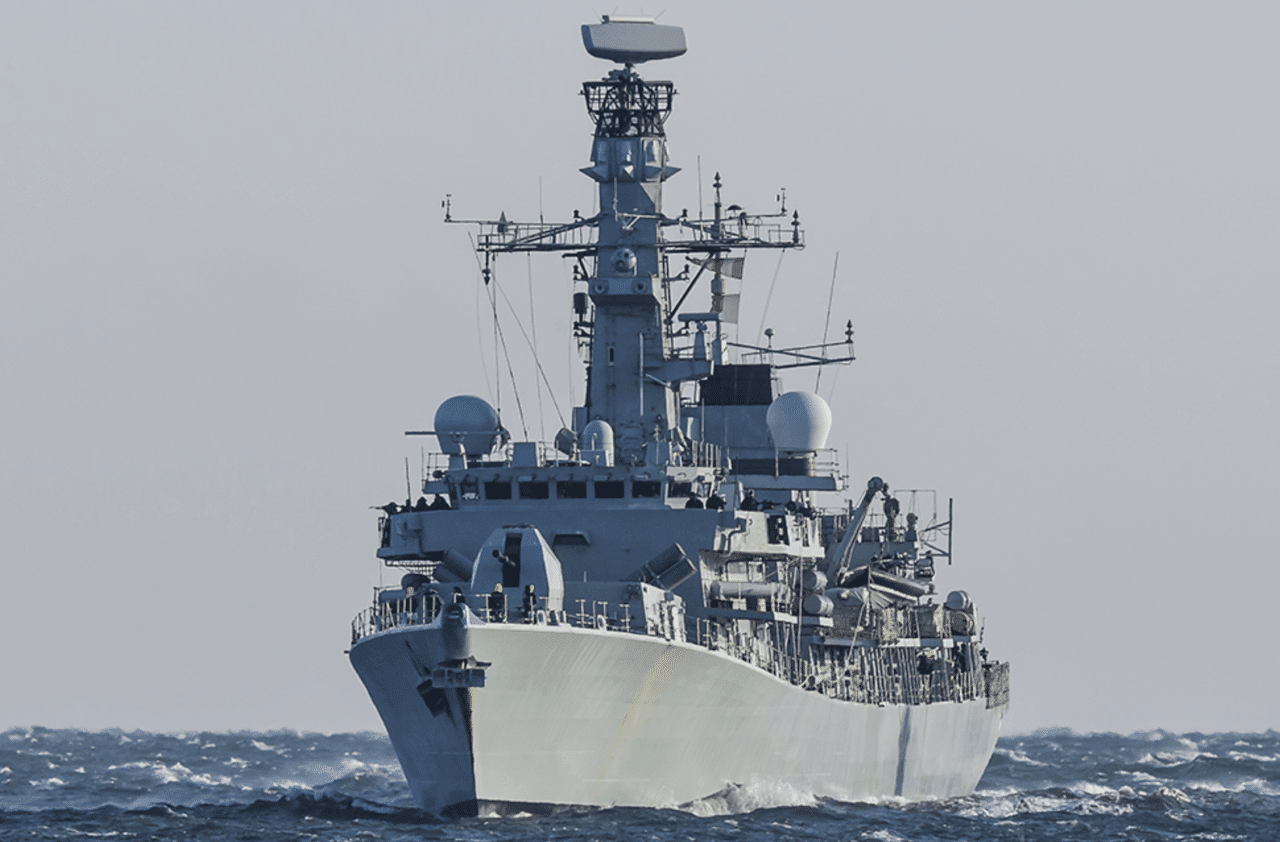

When people think of the items that continue to make the United States military the strongest in the world, they often think of the weapons and advanced technology. While weaponry and high-tech tools are certainly an essential part of the equation, it’s also crucial that military personnel carriers such as naval ships are in peak operating condition.

With that in mind, the nuts and bolts that hold your naval ship together are a critical part of the American defense system. Naval officers know that having access to the best lubricants on the market is vital.

For example, bolt grease is incredibly valuable to help keep America’s naval vessels operating at top performance. Discover today the best use of this grease to perform maintenance on nuts and bolts.

Using Bolt Grease to Maintenance Parts

Take a look at the uses and the benefits derived from this option.

1. Prevents Corrosion

Bolt grease is one of the most potent tools against corrosion, especially when dealing with naval ships that spend so much time in the water.

As you already know, water (especially salt water) creates corrosion and rust on any type of metal surface over time. When dealing with the areas where nuts and bolts are used on naval ships, that corrosion can cause many problems.

Consider the ship’s exterior, where large bolts and nuts are visible in rows. As saltwater and other debris get into those crevices, corrosion is a natural byproduct. When the bolts have proper lubricant in place, that lubricant can help create a barrier between salt, sand, and other substances that can lead to damage on the sides and bottom of the ship.

Additionally, bolt lubricant plays a vital role inside your vessel. When you spend months or even years at sea, the salt and sand that is found in the air can get into the innermost parts of the ship, creating problems in the engine rooms and the other areas where there are countless nuts and bolts.

Ensuring all connections on the ship are properly lubricated cuts down on corrosion, ensuring that the vessel maintains optimal efficiency.

2. Prevents Galling

Galling refers to the natural wear that occurs when two sliding surfaces adhere together.

For instance, the threads on bolts in your ship and the metal they go through are sliding surfaces. Over time, those surfaces can begin to wear, creating a pathway for rust, water, and other debris to get into parts of the vessel that you don’t want to be damaged.

Using the proper grease can help reduce the amount of slippage, which cuts down on galling.

When the thread on a bolt wears down, it ultimately loses effectiveness. This outcome is sometimes referred to as a bolt becoming “stripped.” Eventually, nuts and bolts need to be replaced, but the proper use of lubrication can help extend the lifespan of your existing bolts.

3. Keep Moving Parts Moving

Finally, your naval vessel is made up of countless moving parts. Each of those parts has multiple nuts and bolts that help keep your ship operating properly. In fact, there are more pieces of machinery on the ship than you even realize.

In the same way that engine oil keeps your vessel’s engine operating as you need it to, bolt grease ensures that all your moving parts can keep moving.

When the bolts within the engines on your ship are not properly lubricated, they can seize up. Something as simple as one unlubricated bolt can lead to your ship’s engines failing to operate as designed. That means that bolt grease is integral to keeping your naval vessel operational.

What Can You Do to Maintain Peak Condition?

There is no way to fully recognize all the uses of bolt grease and how it can keep naval ships efficiently and safely defending the freedoms that we hold so dear. With that in mind, the mechanics on your ship must always have an adequate supply of grease.

Additionally, it would help if you set policies and procedures to ensure the following:

- Existing bolts are regularly lubricated.

- Newly installed bolts receive adequate lubrication when they are put into place.

We have been holding America together since 1884, and the United States Navy has kept America safe since 1775. Those longstanding traditions are an excellent reason to choose Dyson for all your connective needs.

In addition to providing Marine & Military solutions, we also love to help keep you informed. Sign up for the Dyson newsletter today to receive helpful tips in your inbox. Send us an email at [email protected] to be added to our list.

We appreciate the opportunity to earn your business, and we are grateful for everything you do to keep America safe.