Thread Rolling and Cutting

Our shop performs both internal and external thread rolling for fasteners and rods to provide you with exactly what you need. We have the machines and expertise to deliver high-quality, large diameter fasteners using the latest thread-rolling technology.

Our Thread Rolling Capabilities

Because we manufacture internally and externally threaded products at the same facility, we have the unique advantage of confirming thread fit of both components. We use high-speed forming presses and automated threading machines to ensure consistency in every order.

We follow standard thread rolling processes, use the latest equipment and technology to ensure the integrity of each part, and follow a clean rolling die process. Each die is a mirror image of the desired thread, the die is placed over cylindrical blanks to form products, and no metal is removed or cut from the blank during this process.

Thread Rolling Capabilities

All of the materials we use for thread rolling are sourced domestically. The result is an American-made product that is ready for use in industrial settings.

Thru-Feed

Infeed

Infeed/Thru-feed

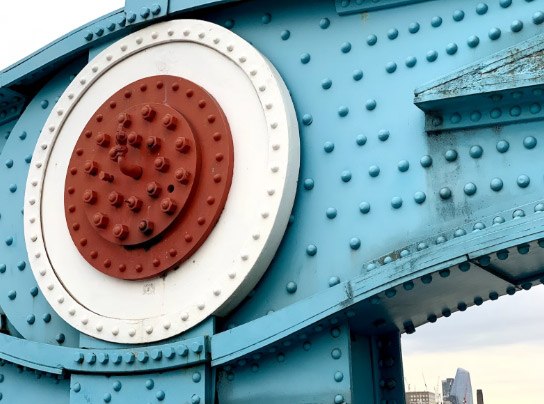

Typical Thread-Rolled Products

- Screws

- Bolts

- Fasteners

Technical Specs

- Thread rolling on threads over 5” in diameter, up to 24”.

- Tapping of products up to 24″ diameter and 60′ in length.

Industries We Serve

Wind Energy

Learn More

Locks and Dams

Learn More

Marine and Military

Learn More

Infrastructure and Construction

Learn More

Oil and Gas

Learn More

Mining

Learn More

Bridges

Learn More