In 2020, the Research Council on Structural Connections (also referred to as the RCSC) modified the language regarding the RCSC specification for structural connections. This development was important news for those who work in the engineering and industrial construction industries.

In addition to providing a safe working environment for those who make up your teams of constructionists, abiding by the regulations set forth by the Research Council on Structural Connections ensures that your jobsite is operating legally. You will also ensure that your project will pass the regular inspections that are a vital part of the process.

Discover more about the revision to RCSC specification and what it means for you.

RSC Specification Change: The Change May Seem Familiar

As a successful engineer, you probably already keep up with the changes that impact the work that you do. With that in mind, the changes implemented by the Research Council on Structural Connections may seem familiar to you. That is because they mirror the language adopted by the American Institute of Steel Construction (AISC) in 2017.

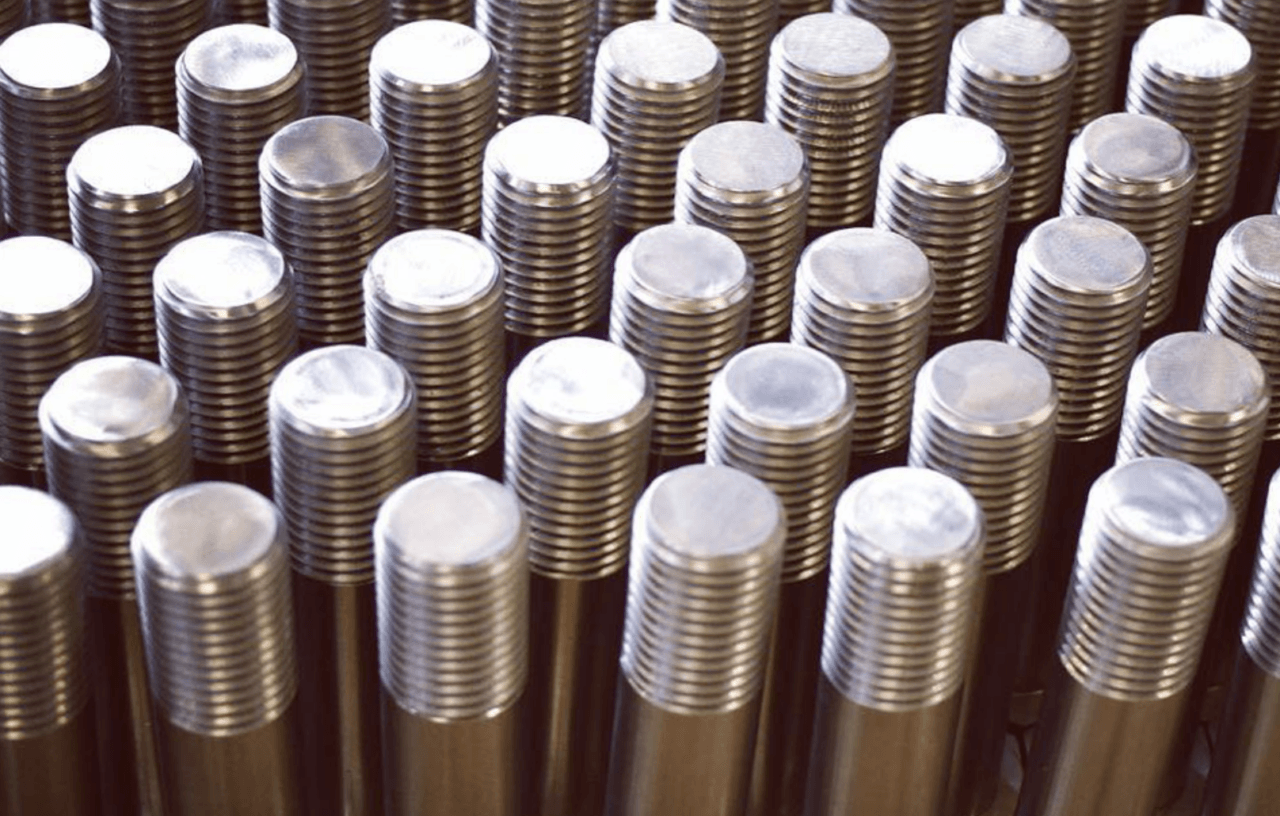

The specification adopted by that entity a few years ago implemented some new policies and procedures regulating the design of bolted joints and the inspection and installation of assembly fasteners in steel connections.

Why Were the Changes Made?

One of the primary reasons for the changes to the RCSC specification for structural joints was to take out unnecessary steps that were formerly required, especially during the manufacturing process.

- These steps added to the costs associated with multiple types of projects.

- The manufacturers passed that cost along to the engineering and construction companies.

- Those companies then passed that cost along to the customers and clients.

One of the most time-consuming and cost-incurring steps of the steel manufacturing process used to include the use of wire brushing on structural steel. Independent research studies conducted by multiple entities concluded that this wire brushing ultimately provided no structural aid and did nothing to increase the anti-slip properties that engineers look for in their materials.

Slippage not only increases the likelihood of injuries during the construction process but also leads to bridges and other large structures experiencing structural failure. While there was formerly a belief that wire brushing increased the slip-resistant nature of steel surfaces, that concept has been debunked. Wire brushing is not only not required, but it is also prohibited.

There are also changes to the language used in previous specifications that are designed to cut down on the slipping that often occurs when high-strength bolts are affixed to a structure.

The standard size of the bolt holes and slot widths were increased for steel bolts that measure 1” or more in diameter. This was done not only to cut down on the amount of slippage that often occurs both during the installation process and over the lifespan of the structure being constructed.

Other Changes to Be Aware Of

While the prohibition of wire brushing and the change in required diameters for steel bolts that are 1” or more in diameter were the primary changes implemented by the RCSC, there are some other changes that you will need to monitor. Specifically, RCSC introduced these other changes:

- Revised the tolerance for turn of nut.

- Clarified the number of gaps permitted.

- Added language to include zinc aluminum coatings to bolts and other surfaces.

How Dyson Corp. Can Help

Dyson Corp. has been holding America together since 1884. With more than 115 years in the industry, we have become one of the most trusted names in construction and engineering.

While our commitment to American-made parts has certainly helped that cause, our prioritization of punctuality has also played an important role. When you need materials for your next project, you need to know that you can get them when you need them.

Additionally, we stay current on all laws, policies, and procedures that affect how engineers support projects.

– We encourage you to subscribe to the Dyson Corp. newsletter today to make sure that you are aware of the latest changes in the industry, such as the revision to the RCSC specification. This way, you can improve how you provide services that your clients need.

To be added to our list, please subscribe in the website footer below so that we can begin sending you valuable information.